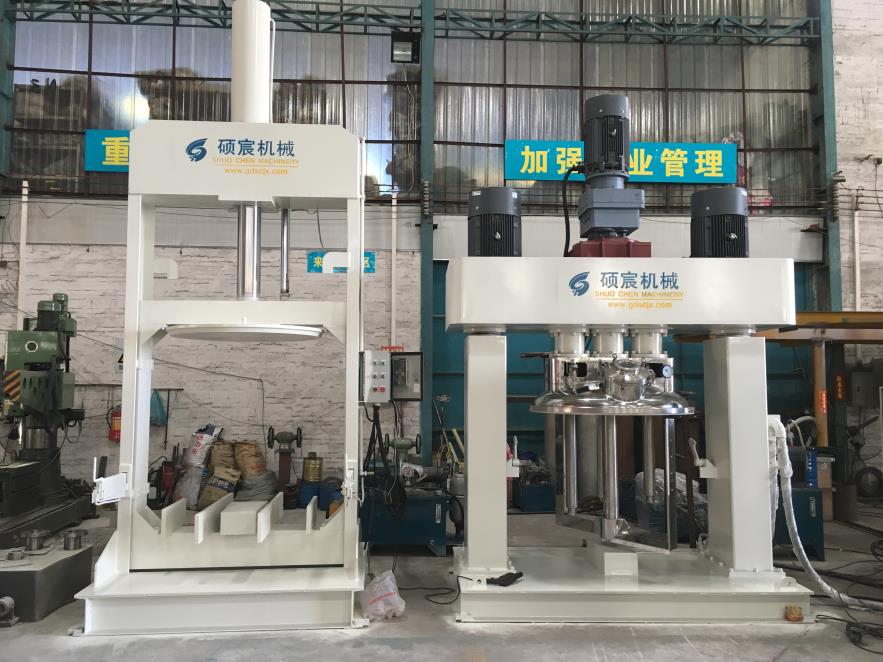

Force dispersing machine

Reaction kettle is a typical main reaction equipment in chemical production. It is widely used in the production of chemical products such as resin, adhesive, paint, cosmetics, pharmaceutical and so on. By mixing, heating and cooling, a variety of materials are dispersed and mixed, so as to conduct reactive polymerization. Its structure is generally composed of kettle body, transmission device, mixing device, heating device, cooling device and sealing device. Corresponding auxiliary equipment: fractionating column, condenser, water separator, collecting tank, filter and so on. You can put forward the amount of processing you need, equipment form, specifications, or the nature of the material you need to process, the sales engineer will provide you satisfied with the program.

Applicable product classification:

1. unsaturated polyester resin, alkyd resin, acrylic resin, oily polyurethane, curing agent, UV resin and other complete sets of production equipment;

2. water polyurethane, acrylic emulsion, white latex, polyvinyl acetate emulsion, carpentry glue, pressure sensitive adhesive and other complete sets of production equipment;

3.107 glue, silicone oil, textile auxiliaries, textile surfactant, printing paste, elastic feeling cowboy pulp and other complete sets of production equipment;

4. hot melt adhesive complete set of production equipment; silicon PU, TUP, EVA and other polymerization equipment;

5.PU glue, yellow glue, adhesive, chloroprene rubber, adhesive, grafting glue, liquid glue, glue and other 502 sets of production equipment;

6. were complete sets of production equipment;

7. paint, coating dispersion, waterproof material, mixing and mixing equipment;

8. waste silica gel cracking, distillation, recovery complete sets of production equipment;

9. grease, microorganism, nanometer material, caulking glue, new building material, wallpaper glue, plastic track;

10. metal pretreatment agent, cleaning agent, electroplating solution, water reducing agent, lithium battery material and other chemical production equipment;

Technical parameter:

1. design volume: 50L-30000L (volume can be designed according to the requirements. )

2. reaction temperature: room temperature -300 degrees or higher, depending on the operating conditions.

3. reaction pressure: -0.1-0.3Mpa.

4. equipment material: SUS304 stainless steel, SUS321 stainless steel, SUS316L stainless steel or Q235-B carbon steel.

5. mixing forms: paddle type, anchor paddle type, frame type, screw belt type, turbine type, dispersed disc type, combination type, etc..

6. heating mode: electric heating, steam heating, water bath heating.

7. heat conduction medium: heat conducting oil, steam, hot water, electric heating.

8. heat transfer structure: jacket, outer tube, inner tube.

9. stirring speed: stirring speed depending on the choice of material mixing of liquid material selection; conventional polymerization speed is 85r/min; containing powder material mixed with the liquid needed to achieve the dispersion effect, speed of 0 - 1500r/min; oil containing two kinds of liquid and liquid or mixed incompatible to achieve the emulsification effect, speed 0 - 2800 r/min.

Characteristics of stainless steel reactor:

1. stainless steel material has excellent mechanical properties, can withstand higher working pressure, but also can withstand the impact of block solid material into the material.

2., good heat resistance, wide temperature range (-196 - 600), at high temperature without oxygen peeling, can be used for direct fire heating.

3. has high corrosion resistance.

4., the heat transfer effect is good, the temperature and cooling speed is fast.

5. has excellent processing performance, can be made according to different process requirements, made a variety of different shape structure of the reactor, but also by grinding and polishing, and materials to achieve good surface finish, but in cleaning and effectively reduce the phenomenon of hanging.

Optimization innovation of reaction kettle:

1. this is a large volume, increase production, reduce production, quality error between the effective way to reduce the product cost and development trend. The reaction kettle for dye production is less than 6000L, and some other industries as 30m fand is 20000 ~ 40000L; foreign in dye industry, and other industries can reach 120 m fand.

2. to replace the cumbersome manual operation with production automation and continuity, such as the use of program control, not only to ensure stable production, improve product quality, increase revenue, reduce physical labor, but also to eliminate environmental pollution.

3. reasonable use of heat energy, select the best operating conditions, strengthen insulation measures, improve the efficiency of heat transfer, so that the heat loss to a minimum, the waste heat or reaction heat generated by the full use of energy. The application of heat pipe technology will be the direction of development in the future.

Applicable product classification:

1. unsaturated polyester resin, alkyd resin, acrylic resin, oily polyurethane, curing agent, UV resin and other complete sets of production equipment;

2. water polyurethane, acrylic emulsion, white latex, polyvinyl acetate emulsion, carpentry glue, pressure sensitive adhesive and other complete sets of production equipment;

3.107 glue, silicone oil, textile auxiliaries, textile surfactant, printing paste, elastic feeling cowboy pulp and other complete sets of production equipment;

4. hot melt adhesive complete set of production equipment; silicon PU, TUP, EVA and other polymerization equipment;

5.PU glue, yellow glue, adhesive, chloroprene rubber, adhesive, grafting glue, liquid glue, glue and other 502 sets of production equipment;

6. were complete sets of production equipment;

7. paint, coating dispersion, waterproof material, mixing and mixing equipment;

8. waste silica gel cracking, distillation, recovery complete sets of production equipment;

9. grease, microorganism, nanometer material, caulking glue, new building material, wallpaper glue, plastic track;

10. metal pretreatment agent, cleaning agent, electroplating solution, water reducing agent, lithium battery material and other chemical production equipment;

Technical parameter:

1. design volume: 50L-30000L (volume can be designed according to the requirements. )

2. reaction temperature: room temperature -300 degrees or higher, depending on the operating conditions.

3. reaction pressure: -0.1-0.3Mpa.

4. equipment material: SUS304 stainless steel, SUS321 stainless steel, SUS316L stainless steel or Q235-B carbon steel.

5. mixing forms: paddle type, anchor paddle type, frame type, screw belt type, turbine type, dispersed disc type, combination type, etc..

6. heating mode: electric heating, steam heating, water bath heating.

7. heat conduction medium: heat conducting oil, steam, hot water, electric heating.

8. heat transfer structure: jacket, outer tube, inner tube.

9. stirring speed: stirring speed depending on the choice of material mixing of liquid material selection; conventional polymerization speed is 85r/min; containing powder material mixed with the liquid needed to achieve the dispersion effect, speed of 0 - 1500r/min; oil containing two kinds of liquid and liquid or mixed incompatible to achieve the emulsification effect, speed 0 - 2800 r/min.

Characteristics of stainless steel reactor:

1. stainless steel material has excellent mechanical properties, can withstand higher working pressure, but also can withstand the impact of block solid material into the material.

2., good heat resistance, wide temperature range (-196 - 600), at high temperature without oxygen peeling, can be used for direct fire heating.

3. has high corrosion resistance.

4., the heat transfer effect is good, the temperature and cooling speed is fast.

5. has excellent processing performance, can be made according to different process requirements, made a variety of different shape structure of the reactor, but also by grinding and polishing, and materials to achieve good surface finish, but in cleaning and effectively reduce the phenomenon of hanging.

Optimization innovation of reaction kettle:

1. this is a large volume, increase production, reduce production, quality error between the effective way to reduce the product cost and development trend. The reaction kettle for dye production is less than 6000L, and some other industries as 30m fand is 20000 ~ 40000L; foreign in dye industry, and other industries can reach 120 m fand.

2. to replace the cumbersome manual operation with production automation and continuity, such as the use of program control, not only to ensure stable production, improve product quality, increase revenue, reduce physical labor, but also to eliminate environmental pollution.

3. reasonable use of heat energy, select the best operating conditions, strengthen insulation measures, improve the efficiency of heat transfer, so that the heat loss to a minimum, the waste heat or reaction heat generated by the full use of energy. The application of heat pipe technology will be the direction of development in the future.